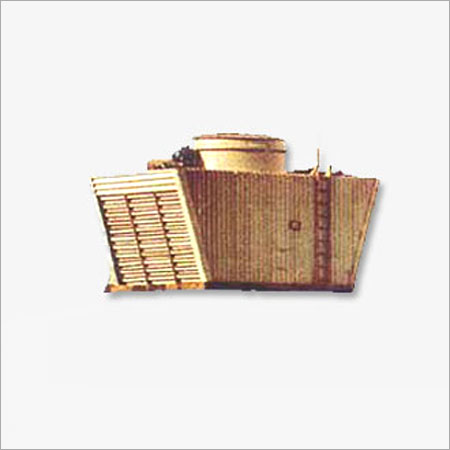

WOODEN COOLING TOWERSThis cooling tower is made with wooden structure, fill and louvers. This mechanism is called as induced draft cross flow cooling.The tower structural and supporting sections are Epoxy Coated/ HDG Steel, fastened with zinc plated/ SS fasteners, and suited for hot, harsh and humid atmospheric industrial conditions. This rugged war horse in our stables, incorporate multi blade, cast aluminum, adjustable pitch fan assembly driven by special T.E, IP-55 protected direct drive/ Geared Motor with low R.P.M and higher air discharge capacities. The standard cladding profile of corrugated asbestos cement sheet or FRP sheet, the joints of which are lapped to minimize water spillage. The Treated Wooden Splash bars, the fill media, are supported on FRP / SS Grids to ensure positive and permanent positioning. The wooden splash bars are of imported pine woods, chemically treated to arrest fungal or algae formations. The design incorporates accommodation of waters with very high TDS factors The hot water from the source when circulated to the collection basin with flower pot nozzles, are sprayed over the fill area. Simultaneously, air is induced through the fill media thus taking away the latent heat from the water passing through the fill media. These towers are generally constructed over RCC sumps designed to accomadate the towers and ensuring adequate air are drawn in to the tower and without escaping else where. Portions of water evaporated, removes the heat from the remaining water. The warm moist air is drawn through the fan deck is discharged to the atmosphere. Cold water, collected at the collection sump, is re-circulated to the heat source. SALIENT FEATURES:

ADVANTAGES

APPLICATIONS

|