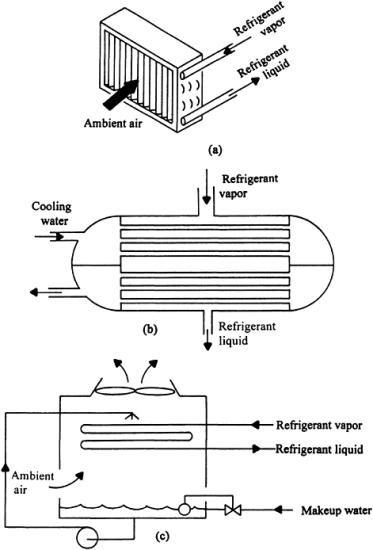

In systems involving heat transfer, a condenser is a device or unit used to condense a substance from its gaseous to its liquid state, by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in chilling plants, air dryer, air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers.

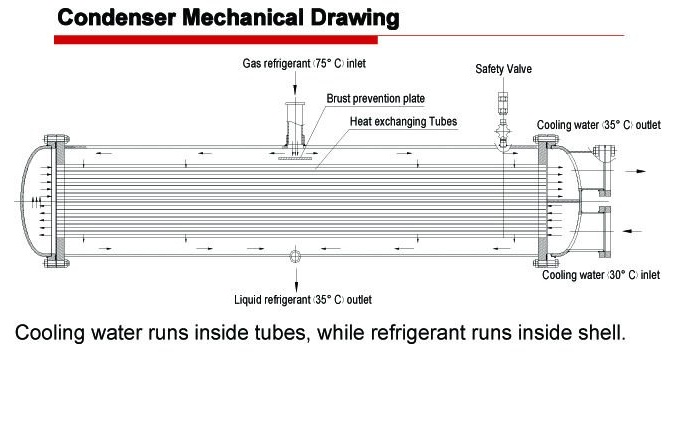

Water cooled – Although a little more pricey to install, these condensers are the more efficient type. Commonly used for swimming pools and condensers piped for city water flow, these condensers require regular service and maintenance.

They also require a cooling tower to conserve water. To prevent corrosion and the forming of algae, water cooled condensers require a constant supply of makeup water along with water treatment.

Depending on the application you can choose from tube in tube, shell and coil or shell and tube condensers. All are essentially made to produce the same outcome, but each in a different way.