PHE TYPE HEAT EXCHANGER

|

AlfacoolTM are manufacturer and supplier of Heat Exchanger , Heat Exchanger is a device that is widely used to enhance or facilitate the flow of heat. These are highly appreciated and acknowledged by our countrywide customers due to its high functionality and affordable prices. Robust constructed Heat Exchanger helps to transfer heat between two or more of fluid. We have different kinds of high quality Heat Exchanger. Which is most demanded for its high usage in different industries and reasonable prices. A heat exchanger is a device used to transfer heat between one or more fluids. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. |

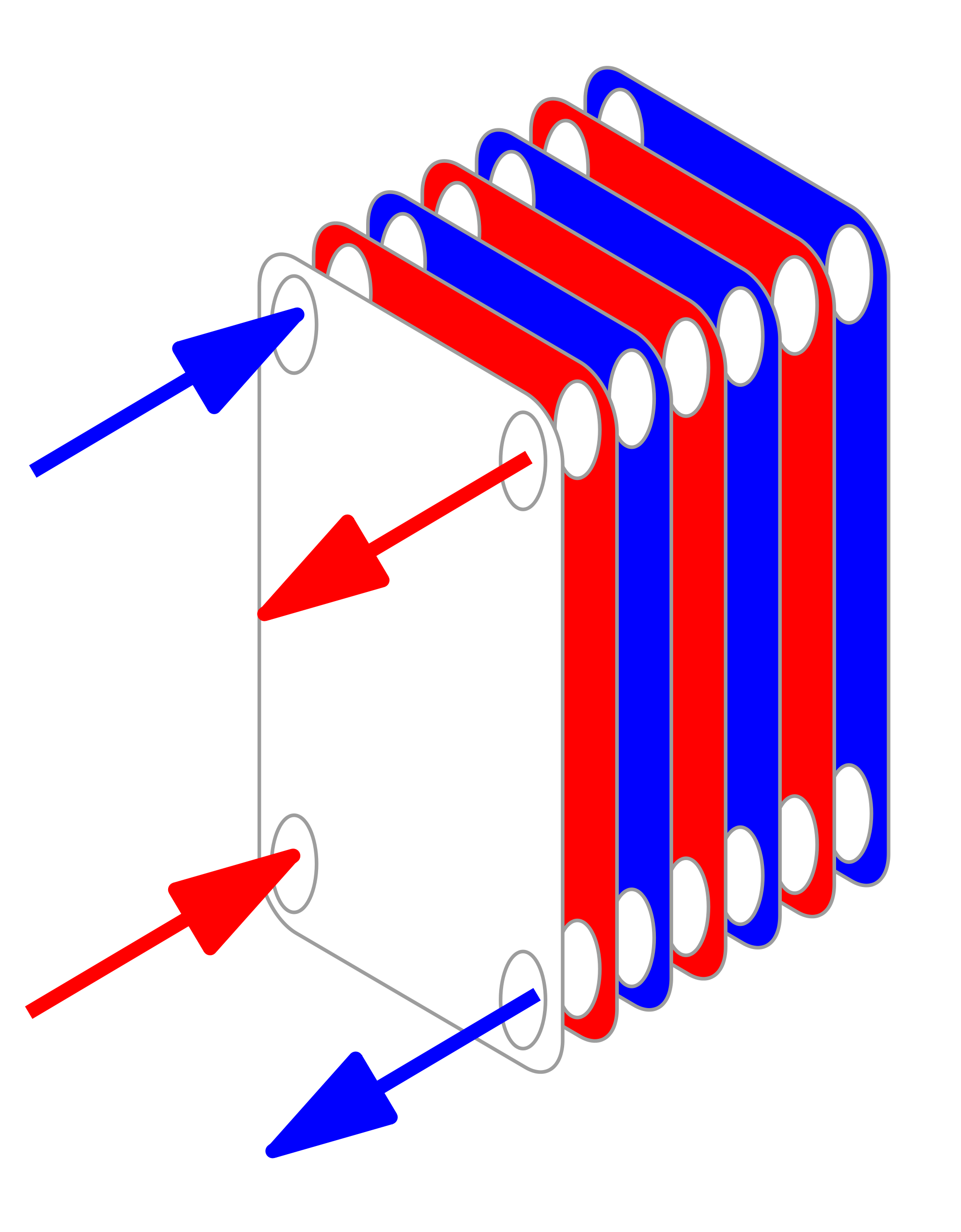

Types :» Plate Heat Exchanger (PHE) Alfacool manufactures Heat Exchanger are in plate type and tube & shell design. In the Heat Exchanger hot water flows in one side & Cold water on other side, thus cold water absorbs heat from the hot water. The design of heat exchanger is done by highly experienced team. Thats why Alfacool plant is highly efficient as its design transfers the heat very fast, These plants are used in Refrigeration system, DG sets, chemical plants, heat treatment, plastic molding machines & process water cooling. The plant made in MS/SS shell, copper & SS Tubes as per the requirement suited to the process. The plants are available in different passages i.e. Single pass, Double pass, Four pass etc. Plate heat exchangerPlate Type heat exchangers consist of series of plates.. These exchangers are composed of many thin, slightly separated plates that have very large surface areas and small fluid flow passages for heat transfer. Advances in gasket and brazing technology have made the plate-type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type are called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently bonded plate heat exchangers, such as dip-brazed, vacuum-brazed, and welded plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with “chevron”, dimpled, or other patterns, where others may have machined fins and/or grooves. When compared to shell and tube exchangers, the stacked-plate arrangement typically has lower volume and cost. Another difference between the two is that plate exchangers typically serve low to medium pressure fluids, compared to medium and high pressures of shell and tube. A third and important difference is that plate exchangers employ more countercurrent flow rather than cross current flow, which allows lower approach temperature differences, high temperature changes, and increased efficiencies. Shell and tube heat exchanger

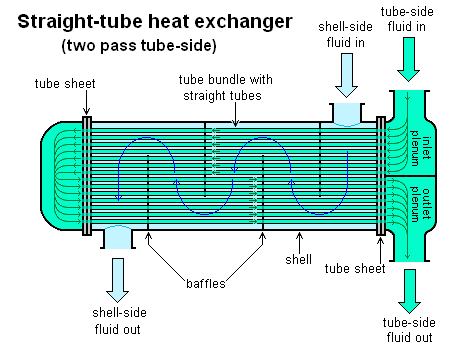

Shell and tube heat exchangers consist of series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and tube heat exchangers are typically used for high-pressure applications (with pressures greater than 30 bar and temperatures greater than 260 °C).This is because the shell and tube heat exchangers are robust due to their shape. Tube diameter: Using a small tube diameter makes the heat exchanger both economical and compact. However, it is more likely for the heat exchanger to foul up faster and the small size makes mechanical cleaning of the fouling difficult. To prevail over the fouling and cleaning problems, larger tube diameters can be used. Thus to determine the tube diameter, the available space, cost and fouling nature of the fluids must be considered. |